-

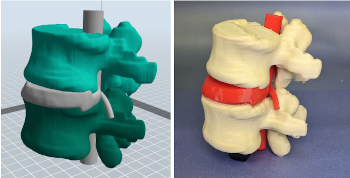

3D printed anatomic models are used in healthcare as aids for training, surgical planning, and patient education. These models are often designed from clinical scans to reflect the actual anatomy of a patient. One focus of our work is exploring the range of materials that can be used in models to simulate the look and feel of real human anatomy.

3D printing allows for the creation of patient-specific devices at a fraction of the time and cost it takes for traditionally manufactured custom implants. Using state-of-art segmentation software and CAD/3D modeling tools,

our group explores how custom devices can be designed and manufactured based on patient medical imaging.

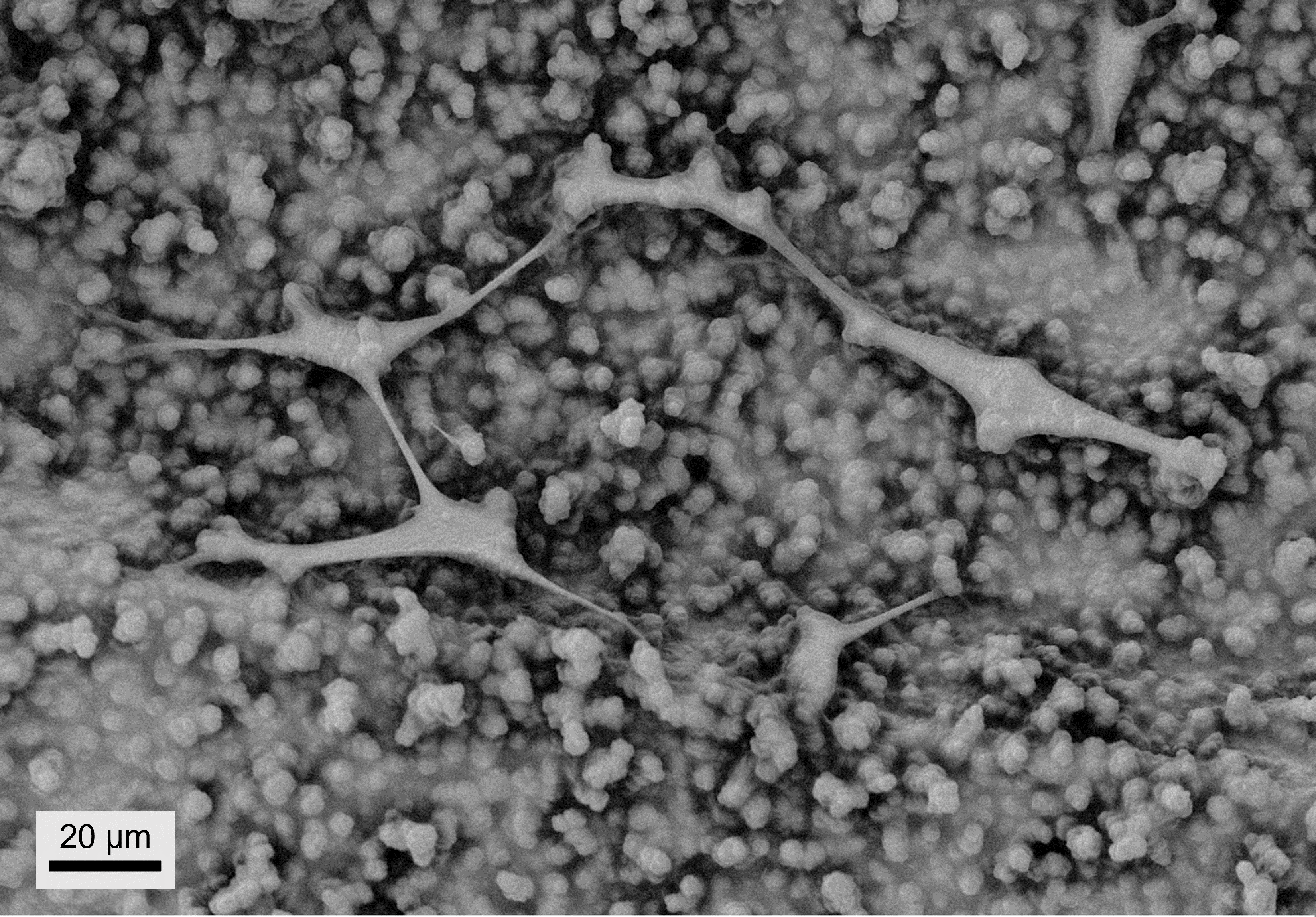

Our research group uses in vitro testing to evaluate the osteo-compatibility of additively manufactured surfaces. MC3T3E1 mouse pre-osteoblasts provide insight into how bone cells will respond to new surfaces, and can be used to determine if new materials are cytotoxic. Cell culture is an important step in the process of evaluating the efficacy of newly researched implants as it also allows our group to confirm that these materials are safe for future animal studies with our collaborators at University of Pennsylvania School of Veterinary Medicine.

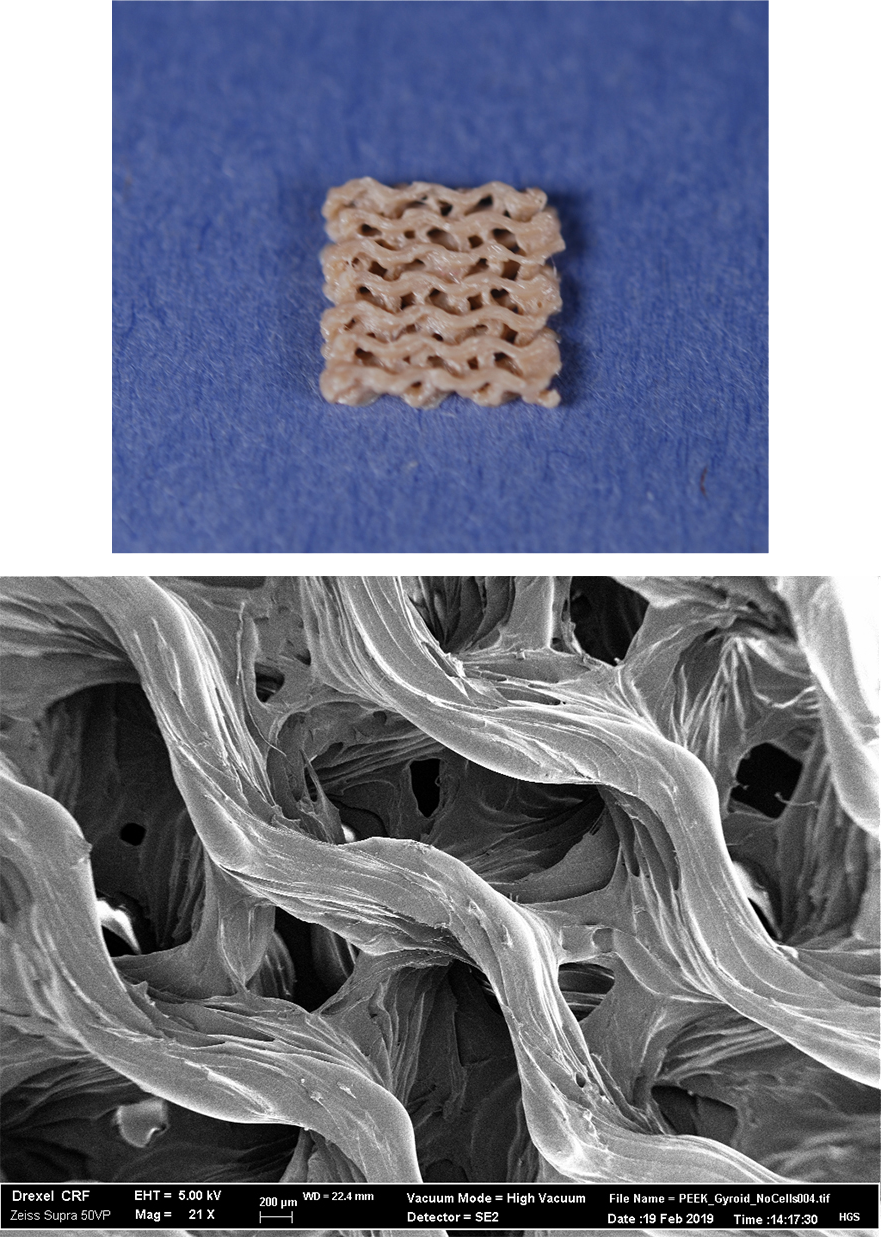

Traditional porous metal surfaces improve osseointegration between bone and metal implants. By utilizing current fused filament fabrication (FFF) techniques, complex structures with interconnected pores can be additively manufactured from PEEK. Our research group is examining the porous architecture for potential use in 3D printed PEEK implants.

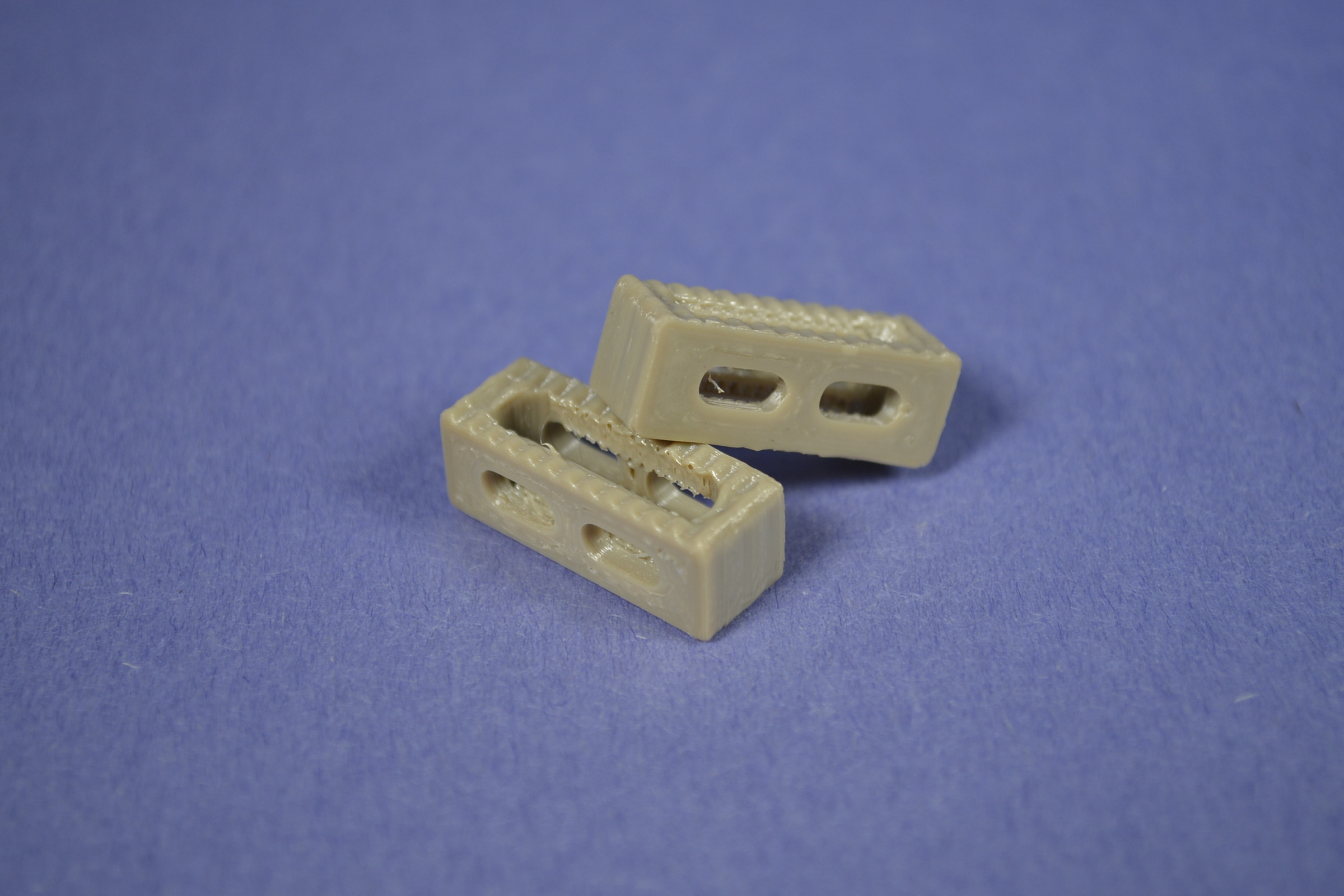

Three-dimensional (3D) printing has emerged as a new frontier for medical device manufacturing. Although relatively new, medical devices and surgical instruments from a range of metallic and polymeric materials are being fabricated with AM techniques. Fused Filament Fabrication (FFF) is one of the AM techniques that has been used in our laboratories for both high and low-temperature polymer printing. Our research group is motivated to examine PEEK spinal cages as well as PEEK porous surfaces produced with this novel manufacturing method.

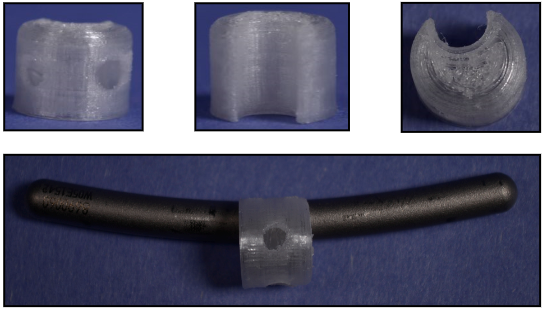

Bioabsorbable polymers are emerging in the world of biomedical engineering with a multitude of uses. Specifically, we are focusing on their development and application with regards to FFF printing. We have developed and validated method to produce filament for FFF printing, including differential scanning calorimetry and gel permeation chromatography. We have successfully 3D printed a bioabsorbable antibiotic-releasing spinal clip for use in conjunction with a rod-screw spinal fusion device for the prevention of surgical site infection. Research concerning this project is still ongoing.